What is Considered High Heat?

Applications involving high levels of radiant heat may require specialized garments with aluminized fabrics to reflect heat energy. Selection can be made according to the needs of the application, such as the level of heat energy, the duration of exposure, the need for a moisture barrier and so on. However, there are several key considerations to keep in mind:

- Temperature is not the only issue. Proximity, duration, and the mass of the heat source all play an important role in a garment’s ability to protect its wearer.

- Performance of the fabric in the ISO 6942 radiant heat resistance tests.

- Because light garments will reduce performance, it is wise to choose loose fitting garments.

- Aluminized garments are specifically designed for radiant heat protection and may not provide effective protection against other types of heat hazard.

- Garments must be kept clean and in good order, as dirty garments will not reflect heat energy. The aluminized surface can be washed by wiping down with a soft cloth and should be dried by hanging.

- As with all heat protective garments, underclothing must not be of a synthetic or flammable nature and ideally should meet minimum FR performance characteristics.

Standards for High Heat Protective Clothing

There are individual tests for convective, radiant and contact heat, and two further tests for molten metal splash (iron and aluminum).

Each of the three heat resistance tests places fabric between a heat source and a calorimeter, recording the time until a specific rise in temperature is achieved. The longer it takes to record the rise in temperature, the better the fabric is at resisting energy transfer, offering a higher the level of protection. Results are classified as Class 1, 2 or 3 (3 the highest) according to times indicated in the standard. However, the radiant heat test (ISO 6942 Method B) features the four classifications described below.

The introduction to the standard explains that Classes 1, 2, and 3 can be generally referenced as levels of protection for low, medium, and high-risk applications, but the fourth performance level is used for radiant heat. Class 4, recording a time of over 95 seconds, is specifically designed for high radiant heat applications and testing of aluminized garments. Aluminized PPE should achieve Class 4 (a result over 95 seconds).

PPE for High Heat Protection

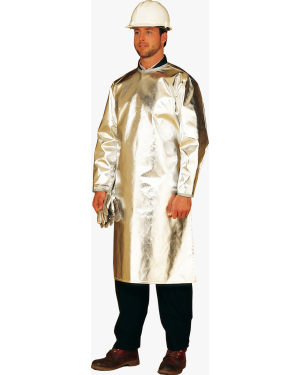

Clothing to protect against high levels of radiant heat relies on the fact that it can be reflected by a shiny surface, meaning that high heat PPE is commonly constructed with reflective materials. Gold, having a very high reflectivity, would be an ideal choice and a thin layer is often used on visors. However, gold is too heavy, and too expensive. Aluminum is light, flexible, and relatively inexpensive, making it a reliable and cost-effective choice.

Aluminized garments can provide sufficient reflection of heat energy to protect workers from high heat hazards. Depending on the intended application, aluminized fabric may feature one or more layers.

-

- Low Risk High Radiant Heat Applications: A single layer of aluminum on a woven substrate of a heat resistant, woven, meta-aramid fabric.

- Low Risk High Radiant Heat Applications where steam or liquid is present: A moisture barrier is added on the inside.

- Extreme Radiant Heat Applications: A further layer of quilted heat resistant material to provide additional heat energy filtration is added.

Not all aluminized garments feature 100% aluminum surface. In some cases, to reduce cost, manufacturers use a fabric that is a mix of aluminum with a polymer. This does reduce the price, but it also reduces the reflectivity and can result in lower performance. For this reason, especially with cheaper high heat protective clothing, it is important to ask if the surface is 100% aluminum. You should also ask how the fabric performs in a Radiant Heat Resistance Test.

The Importance of Correct Use and Maintenance

Aluminized clothing often comes in a coat and pants configuration, with separate boots, gloves, and a hood with visor. However, there are important considerations for users:

- The temperature of the heat source is not the only factor to consider. Whether a worker is sufficiently protected or not will also depend on several other factors:

- Proximity to the source has a major effect on how much energy reaches the worker. The closer to the source the greater the energy flow.

- Duration of exposure. A shorter exposure will result in less energy transfer than a longer.

- Mass or Volume of the heat source. A large heat source will emit more heat energy than a small.

- The physiology of the wearer. Some people can handle heat energy better than others.

Thus, selection and use of garments should only be undertaken following a risk assessment, considering all relevant factors, by qualified safety personnel.

- Aluminized garments are designed to reflect heat energy and may not be effective at protecting against other forms of energy transfer. For example, if the ambient air temperature is very high, a coat and pants aluminized suit will not prevent the high temperature air entering the suit and causing burns.

- Aluminized garments work because the shiny surface reflects the heat energy. So, if the garment becomes damaged, worn or dirty it will not work, and the wearer may not be protected. It is vital to keep aluminized garments clean and in good order.

- Aluminized garments are deliberately over-sized and baggy. The air between the fabric and the wearer is important additional heat energy insulation. It is better to choose larger, rather than tighter, fitting suits.

- Aluminized clothing is necessarily heavy and bulky. Working in it with high heat applications is exhausting and stressful, so management of tasks to minimize the risk of heat stress is vital. Consider wearable technology to monitor the wellbeing of workers such as Bodytrak, especially in the case of extreme or longer duration applications.

Protect Your People From High Heat

High Heat FAQ